Sintered Metal Fiber for High Efficient Capability

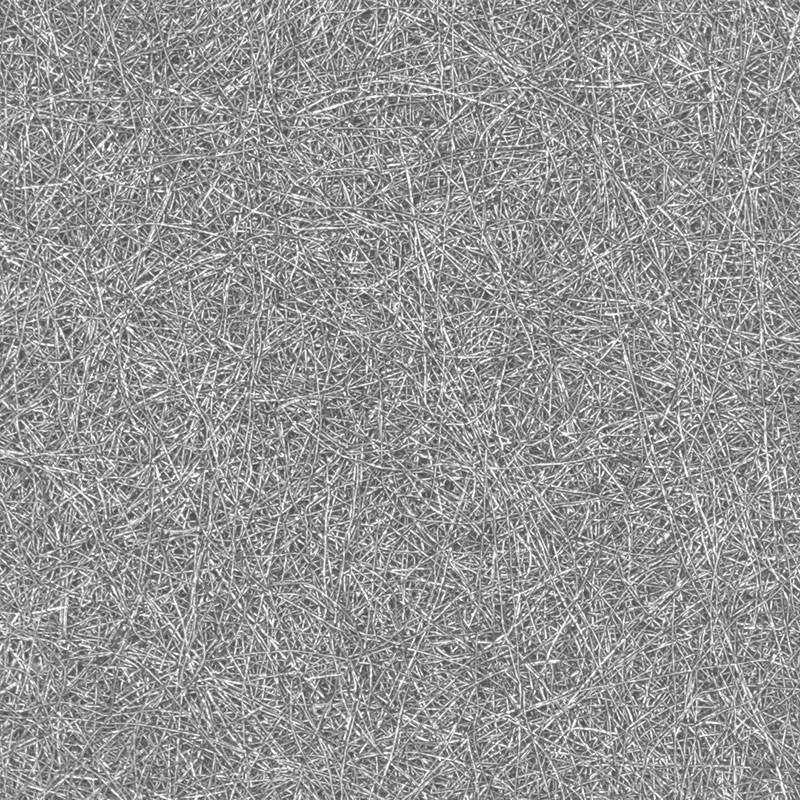

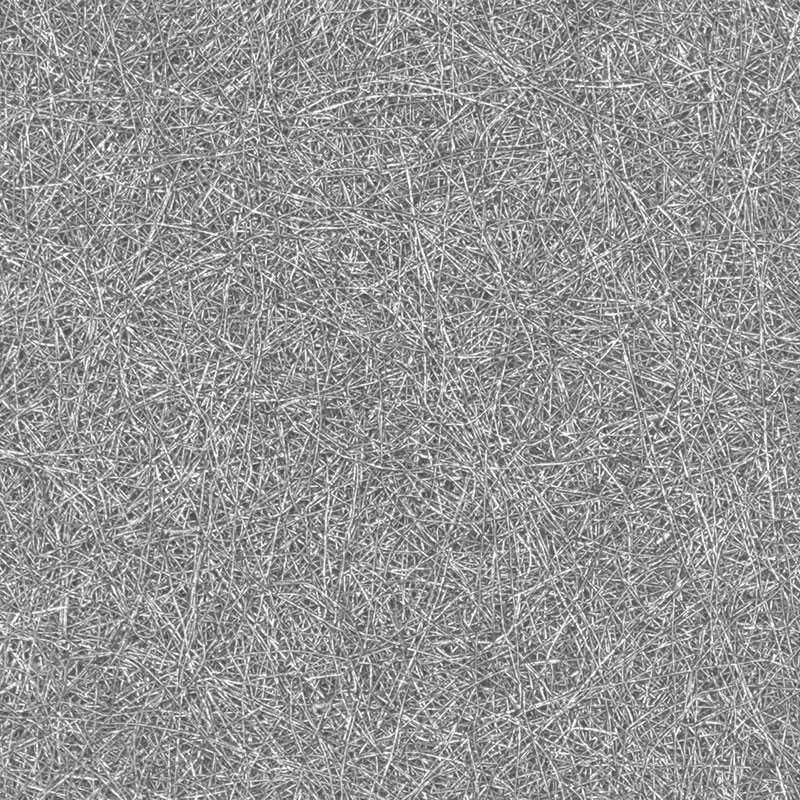

Stainless Steel Sintered Fiber

The stainless steel sintered fiber has a pore gradient formed by layers of different pore sizes, We can achieve extremely high filtration accuracy and greater pollution capacity by controlling it. It has the characteristics of three-dimensional network, porous structure, high porosity, large surface area, uniform pore size distribution, etc, and can continuously maintain the filter effect of the filter cloth.because of the above structure and characteristics, the stainless steel sintered fiber can effectively make up for the weakness of the metal mesh that is easy to be blocked and damaged. It can make up for the fragility and low flow rate of powder filtration products, It possesses temperature and pressure resistance that cannot be compared to ordinary filter paper or filter cloth. Therefore, stainless steel metal sintered fiber is an ideal filter material for high temperature resistance, corrosion resistance and high precision.

Model ①: C4

It is a high porosity product with high dirt holding capacity. Its characteristic is that it has a longer service life when used in medium-pressure and medium-high pressure environments.

Features

(1) multi-layer structure.

(2) better compression resistance.

(3) foldable.

(4) high dirt holding capacity.

Advantages

(1) Use longer online life under high pressure drop.

(2) Better washability and thus a longer service life.

Product Specifications

| Model | Average bubble point pressure Pa | porosity% | Air permeability I/dm².min |

| 5C4 |

7400 |

73 |

32 |

| 7C4 |

5100 |

73 |

54 |

| 10C4 |

3700 |

73 |

75 |

| 15C4 |

2400 |

73 |

180 |

| 20C4 |

1850 |

73 |

230 |

| 25C4 |

1500 |

73 |

294 |

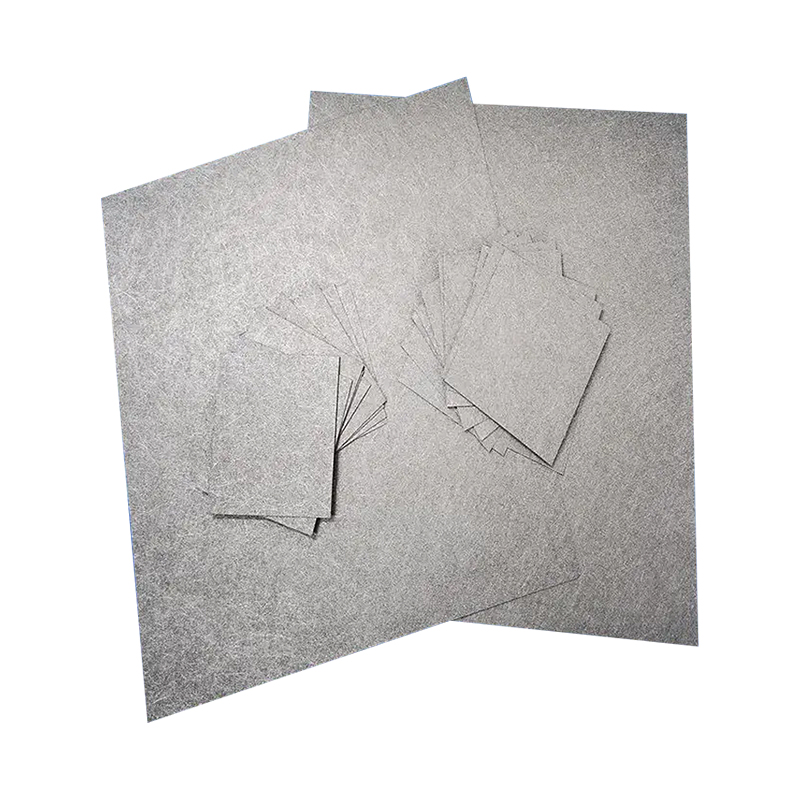

Standard size

1500*1180mm

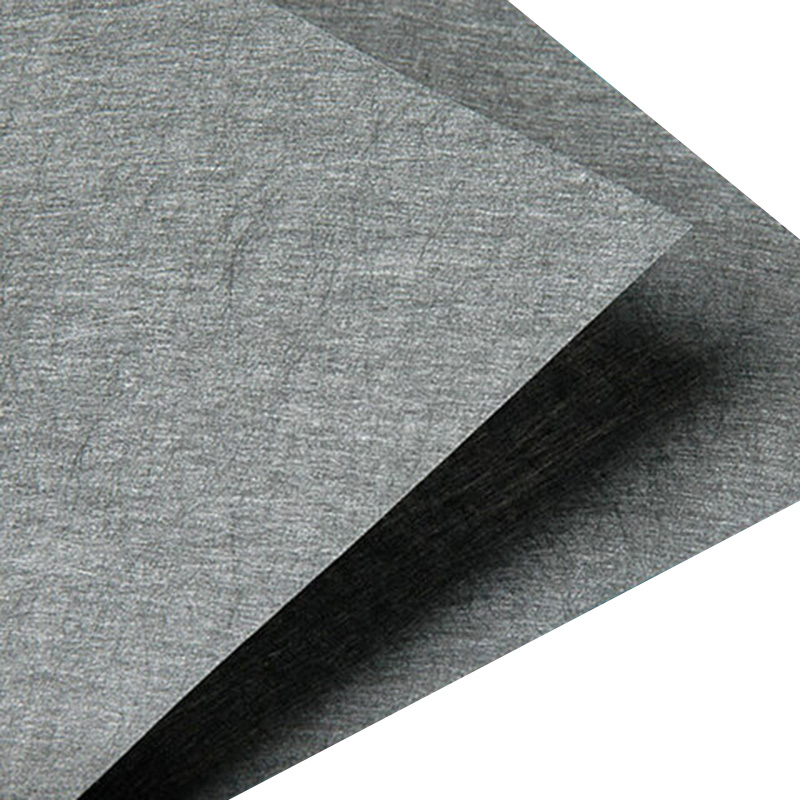

Sintered fiber with protective mesh

Sintered fiber with single sided protective mesh and Sintered fiber with double-sided protective mesh.

Application fields

Polyester chips, chemical fiber, High temperature melt filtration, film industry, Polymer Materials, etc.

Application products

Wire mesh filter, filter screen, candle filter, filter pan, etc.

Model ②: A3

It is widely used and pleated filter material, which can be widely used in the filtration of polymerization and spinning processes, and is also suitable for the filtration of other liquids.

Features

(1) multi-layer structure.

(2) high porosity.

(3) good compressive performance.

(4) foldable.

(5) various filtering precision.

Advantages

(1) flexible application.

(2) good dirt-holding capacity.

(3) good online life.

Product Specifications

| Model | Average bubble point pressure Pa | Porosity% | Air permeability I/dm².min |

| 3A3 |

12300 |

67 |

10 |

| 5A3 |

7600 |

80 |

34 |

| 7A3 |

5045 |

74 |

62 |

| 10A3 |

3700 |

78 |

108 |

| 15A3 |

2470 |

80 |

180 |

| 20A3 |

1850 |

82 |

265 |

| 25A3 |

1480 |

79 |

325 |

| 30A3 |

1235 |

79 |

450 |

| 40A3 |

925 |

76 |

620 |

| 60A3 |

630 |

86 |

1350 |

| 75A3 |

480 |

84 |

1470 |

| 80A3 |

450 |

85 |

1510 |

| 90A3 |

410 |

88 |

1740 |

| 100A3 |

360 |

89 |

2020 |

Standard size

1500*1180mm

Sintered fiber with protective mesh

Sintered fiber with single sided protective mesh and Sintered fiber with double-sided protective mesh.

Application fields

PET, PP, PAN and other polymers, film industry, Polymer Materials, etc.

Application products

Spin pack filter, pack filter, candle filter, filter pan, etc.

Model ③: C3

The best choice for low-viscosity fluid filtration, suitable for filtration of monomers, prepolymers, raw materials, etc.

Features

(1) multi-layer structure.

(2) high dirt holding capacity.

(3) high porosity.

(4) foldable.

Advantages

(1) Better washability.

(2) Longer online life.

(3) Low pressure drop.

Product Specifications

| Model | Average bubble point pressure Pa | Porosity% | Air permeability I/dm².min |

| 5C3 |

7100 |

86 |

37 |

| 10C3 |

3500 |

85 |

110 |

| 15C3 |

2400 |

85 |

203 |

| 20C3 |

1700 |

86 |

345 |

| 25C3 |

1700 |

86 |

385 |

| 30C3 |

1230 |

86 |

650 |

| 40C3 |

1036 |

86 |

675 |

Standard size

1500*1180mm

Sintered fiber with protective mesh

Sintered fiber with single sided protective mesh and Sintered fiber with double-sided protective mesh.

Application fields

PET, PP, PAN and other polymers, Biomedicine and Food & Beverage, etc.

Application products

Spin pack filter, pack filter, candle filter, filter pan, etc.

Model ④: D4

A high-strength sintered fiber specifically designed for polymer disc filtration.

Features

(1) multi-layer structure.

(2) high weight and high sintered strength.

(3) low porosity.

(4) non-foldable.

(5) high dirt holding capacity.

Advantages

(1) Good pressure resistance.

(2) Long service life.

Product Specifications

| Model | Average bubble point pressure Pa | Porosity% | Air permeability I/dm².min |

| 2D4 |

18000 |

51 |

3 |

| 3D4 |

12300 |

72 |

13 |

| 5D4 |

7700 |

72 |

24 |

| 7D4 |

5000 |

72 |

43 |

| 10D4 |

4020 |

72 |

53 |

| 12D4 |

3200 |

72 |

85 |

| 15D4 |

2410 |

72 |

135 |

| 20D4 |

1900 |

72 |

165 |

| 25D4 |

1480 |

71 |

260 |

| 30D4 |

1230 |

75 |

350 |

| 40D4 |

925 |

75 |

625 |

Standard size

1500*1180mm

Sintered fiber with protective mesh

Sintered fiber with single sided protective mesh and Sintered fiber with double-sided protective mesh.

Application fields

Optical film, lithium battery separator, carbon fiber.

Application products

Leaf disc.

Model ⑤: B3

Specially designed for the filtration of fluids with low viscosity, low pressure drop and low impurity content (such as hydraulic oil, fuel, etc.)

Features

(1) single-layer structure.

(2) high porosity.

(3) foldable.

(4) low dirt holding capacity.

Advantages

(1) For low viscosity fluid filtration, small pressure drop.

(2) Light weight.

(3) Easy application.

Product Specifications

| Model | Average bubble point pressure Pa | Porosity% | Air permeability I/dm².min |

|

5B3 |

7000 |

79 |

45 |

|

10B3 |

3700 |

81 |

125 |

|

15B3 |

2470 |

78 |

250 |

|

20B3 |

1850 |

80 |

400 |

|

40B3 |

925 |

84 |

1100 |

|

60B3 |

530 |

74 |

1660 |

Standard size

1500*1180mm

Sintered fiber with protective mesh

Sintered fiber with single sided protective mesh and Sintered fiber with double-sided protective mesh.

Application fields

Mechanical equipment hydraulic oil, lubricating oil filtration.

Application products

Pleated Candle Filter, cylinder candle filter, Oil Filter, spin pack filter.

Model ⑥: F3

Economical sintered fiber, light weight, high cost performance.

Features

(1) single-layer structure.

(2)foldable.

(3) medium dirt-holding capacity.

Advantages

(1) more economical.

(2) easy to clean.

Product Specifications

| Model | Average bubble point pressure Pa | Porosity% | Air permeability I/dm².min |

|

10F3 |

3500 |

71 |

90 |

|

15F3 |

2600 |

77 |

140 |

|

20F3 |

1800 |

70 |

240 |

|

40F3 |

925 |

71 |

625 |

|

60F3 |

550 |

71 |

1200 |

Standard size

1500*1180mm

Sintered fiber with protective mesh

Sintered fiber with single sided protective mesh and Sintered fiber with double-sided protective mesh.

Application fields

Petroleum & Chemica, Chemical fiber & Film, coal mine industry, ocean vessel, metallurgical industry.

Application products

Stainless Steel Candle Filter, spin pack screen filter.

Model ⑦: E4

Multi-layer structure filter felt specially designed to improve pleat performance.

Features

(1) multi-layer structure.

(2) symmetrical structure.

(3) good folding performance.

(4) high dirt holding capacity.

Advantages

High wrinkle resistance.

Product Specifications

| Model | Average bubble point pressure Pa | Porosity% | Air permeability I/dm².min |

|

3E4 |

11500 |

70 |

10 |

|

5E4 |

8000 |

81 |

36 |

|

7E4 |

5300 |

68 |

40 |

|

10E4 |

3700 |

74 |

75 |

|

15E4 |

2466 |

71 |

132 |

|

20E4 |

1850 |

71 |

220 |

Standard size

1500*1180mm

Sintered fiber with protective mesh

Sintered fiber with single sided protective mesh and Sintered fiber with double-sided protective mesh.

Application fields

Plastic extrusion, chemical process, liquid filtration,crude oil process, polymer filtration, filtration for refine process.

Application products

Pleated Candle Filter, pack filter.