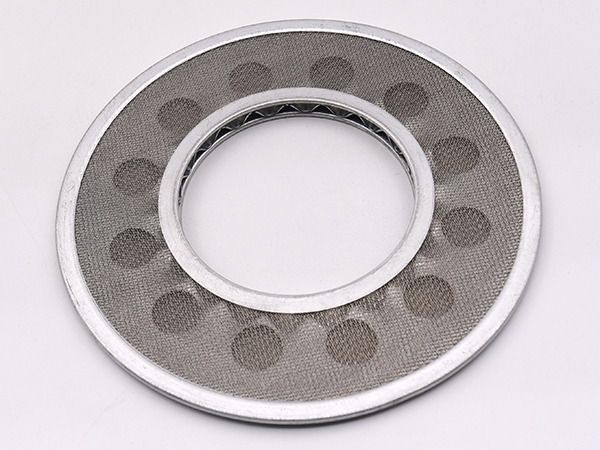

Spin Pack Filter in Metal Media

Spin Pack Filter

It is made of metal mesh with different mesh sizes that are stamped , then assembled in a certain order into the already processed edge wrapping ring and finally pressed. Its function is to filter the molten material flow and increase the resistance of the material flow, so as to filter out mechanical impurities and improve the effect of mixing or plasticizing. It has properties such as acid resistance, alkali resistance, temperature resistance, and wear resistance; it is mainly used in mining, petroleum, chemical, food, medicine, machinery manufacturing, Chemical fiber spinning and other industries.

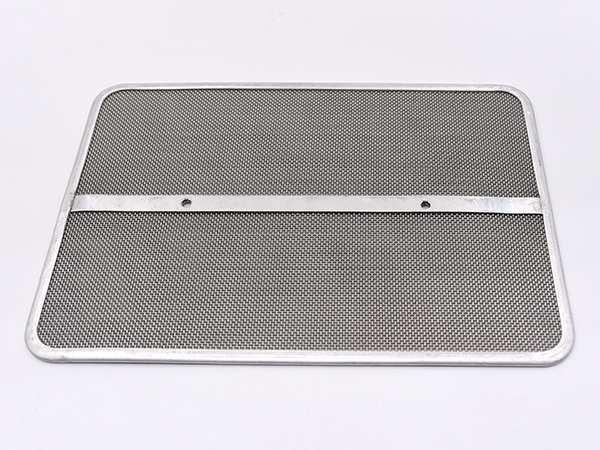

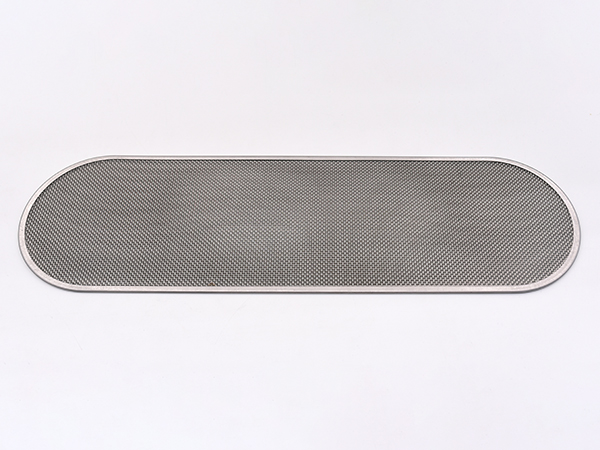

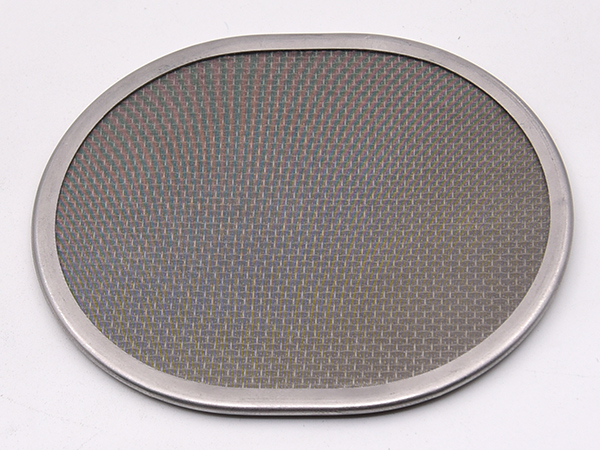

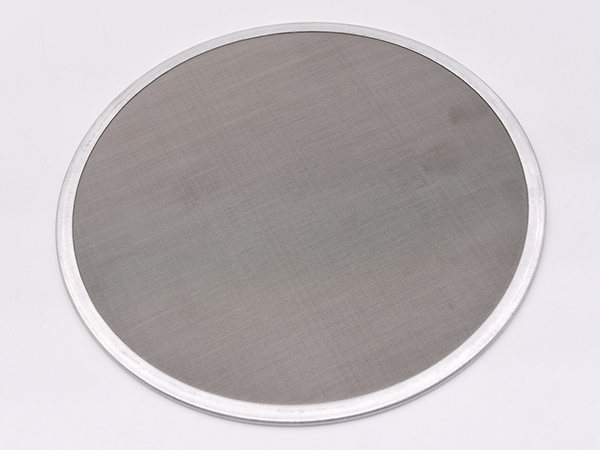

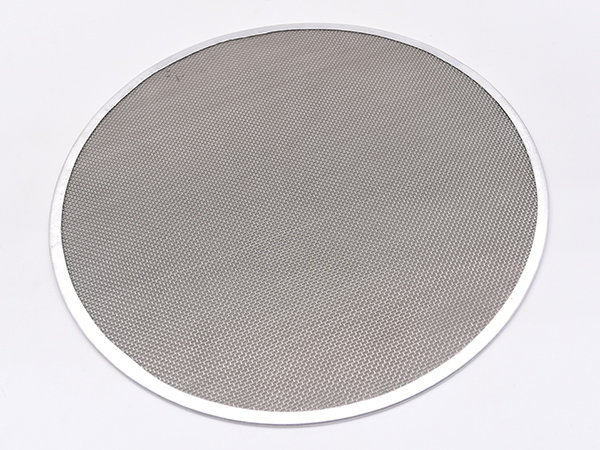

Flat Surface

The screen surface of this spin pack filter is flat.

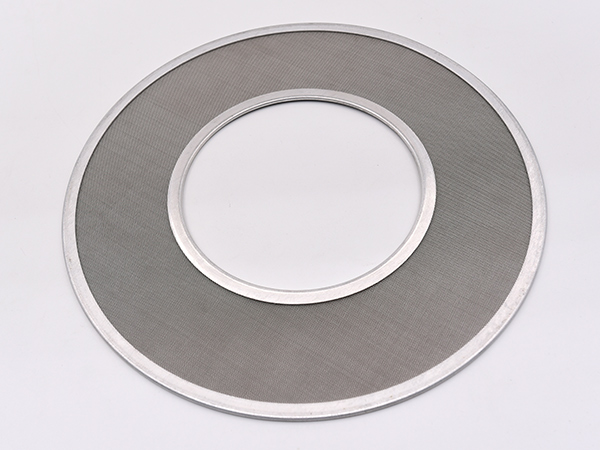

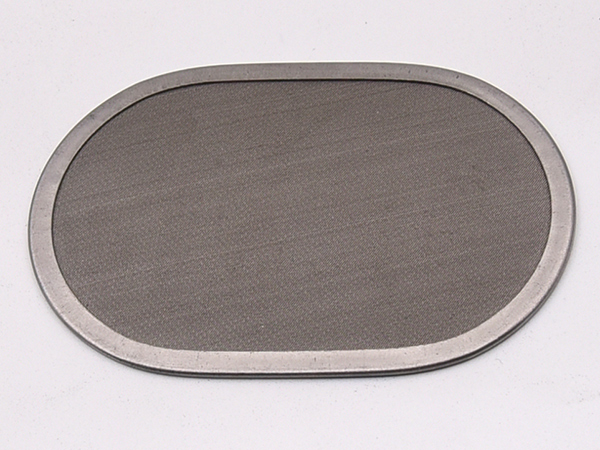

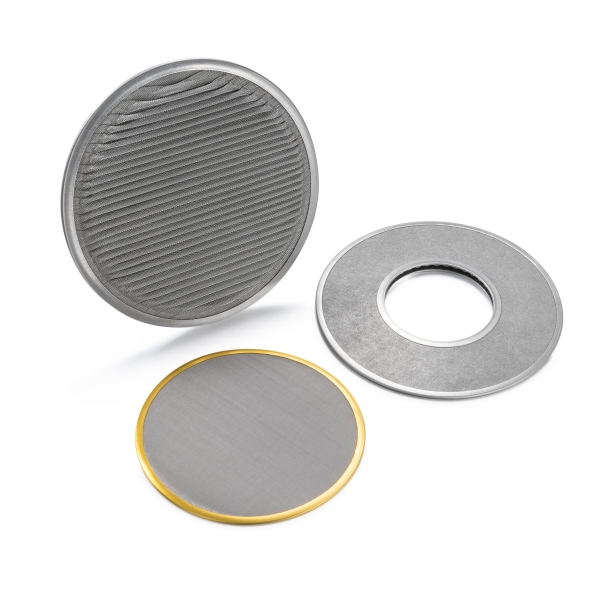

Classified according to the shape of spin pack filter: round, rectangular, semicircular, waist-shaped, hollow, special-shaped.

Classified by edge wrapping materials: aluminum, copper, stainless steel, rubber.

Classified by the surface treatment of edge wrapping materials: copper edge nickel-plated, aluminum edge anodized dyeing treatment.

Classified by main filter layer: sintered fiber, dutch weave, wire mesh.

★ The external dimensions and the number of filter mesh layers can be customized according to actual needs.

Pleated

The filter mesh of spin pack screen filter is pleated

Classified according to the shape of spin pack filter: round, rectangular, semicircular, waist-shaped, hollow, special-shaped (with pictures)

Classified by edge wrapping materials: aluminum, copper, stainless steel, rubber (with pictures attached)

Classified by the surface treatment of edge wrapping materials:copper edge nickel-plated,aluminum edge anodized dyeing treatment.

Classified by main filter layer:sintered fiber,dutch weave,wire mesh.

★ The external dimensions and the number of filter mesh layers can be customized according to actual needs.

Cylinder Or Cone

The shape of this spin pack filter is cylindrical or conical

Classified by edge wrapping materials: aluminum, copper, stainless steel (with pictures attached)

Classified by the surface treatment of edge wrapping materials: copper edge nickel-plated,aluminum edge anodized dyeing treatment. (with pictures attached)

Classified by main filter layer:sintered fiber, dutch weave, wire mesh.

★ The external dimensions and the number of filter mesh layers can be customized according to actual needs.

SPL Filter

It is made of different metal mesh and support frame that are stamped , then assembled in a certain order into the already processed edge wrapping ring and finally pressed.

Features

The SPL filter is a filter made of wire mesh, which has the characteristics of high strength, high oil permeability, reliable filtration, and easy cleaning.

Application Fields

(1) Suitable for filter press oil filtration, oil circuit system filtration of marine diesel engines and other equipment.

(2) Applicable to the filtration of various types of thin oil lubrication devices.

(3) To improve the cleanliness of oil in various industrial fields such as petroleum, electricity, chemicals, metallurgy, etc

(4) Filtration of impurities in textile raw fluids under various types of spinning nozzles and other similar conditions for synthetic and synthetic fiber textiles in the chemical fiber industry.

Model Parameters

| Model | Nominal diameter DN | Rated flow m³/h(L/min) | Size mm | ||

| Binocular series | Monocular series | ID | OD | ||

| SPL15 | 15 | 2(33.4) | 20 | 40 | |

| SPL25 | DPL25 | 25 | 5(83.4) | 30 | 65 |

| SPL32 | 32 | 8(134) | |||

| SPL40 | DPL40 | 40 | 12(200) | 45 | 90 |

| SPL50 | 50 | 20(334) | 60 | 125 | |

| SPL65 | DPL65 | 65 | 30(500) | ||

| SPL80 | DPL80 | 80 | 50(834) | 70 | 155 |

| SPL100 | 100 | 80(1334) | |||

| SPL125 | 125 | 120(2000) | 90 | 175 | |

| SPL150 | DPL150 | 150 | 180(3000) | ||

| SPL200 | DPL200 | 200 | 320(5334) | ||

Product Display